The Perko® Story

The PERKO® Story consists of many interesting pieces. They make up a modern day marine hardware success story that goes back over 100 years!

EARLY BEGINNINGS

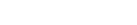

The story starts with Frederick Persky, who later became known as Frederick Perkins. He was a Russian immigrant who was schooled in Germany as a machinist and tool-and-die maker. Frederick came to the United States in the early 1890's and soon became employed as a machinist for E.W. Bliss & Company in Brooklyn, New York. In the early 1900's, he and a partner began operating a business, F. Persky & Company, Lantern Manufacturer, out of the basement of his house.

1900-1907

In 1907, Frederick's son Louis joined him in the business, and together they enlarged both the product line and the manufacturing facilities. By 1912, they had seventeen employees and made a wide range of marine lanterns and products.

1907-1912

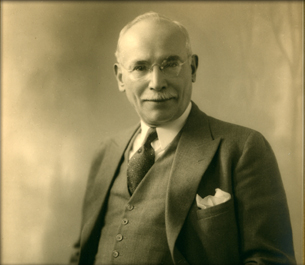

The business continued operating until 1913 when Frederick became president of National Marine Lamp Company, based out of Forestville, Connecticut. Frederick and Louis left that company in 1916 and moved back to Brooklyn, New York, where they started Perkins Marine Lamp Corporation. Five generations later, PERKO® is still a privately owned, family operated corporation, which is unusual in today's marketplace.

1913-1916THE PERKINS MARINE LAMP CORPORATION

Perkins Marine Corporation was initially known as Perkins Marine Lamp, Inc. The original focus was on the manufacture of hand formed sheet metal products for the marine market. The first catalog was published in 1916, with a product line as diverse for its time as PERKO®'s catalog is today.

It included a full range of kerosene and electric lanterns for small and large boats, ventilators, chart cases, signaling devices, mooring buoys, pumps and a variety of spare parts. These products, fabricated from brass, copper and galvanized sheet metal, began what was our ongoing reputation for producing high quality products. We still do some hand forming and soldering today, much as it was done in our early years.

1916-1921

In 1922, the "PERKO®" trademark was instituted. Each new product (and there were many) utilized the latest, sophisticated metal manufacturing technology and customers came to expect the highest standard of excellence from PERKO® products.

1922

1930'S GROWTH AND EXPANSION

The company name was changed to Perkins Marine Lamp and Hardware Corporation in 1932 to better reflect the growing line of products being offered at that time.

The company enjoyed exceptional growth into the 1930's as our reputation for quality increased, and new manufacturing facilities were added. The original one story plant grew to five stories and six more buildings under the direction of Louis Perkins. By the time Frederick Perkins passed away in 1947, Perkins Marine Lamp and the PERKO® trademark had become a major factor in the fast growing marine industry.

1932-1947

MOVE TO FLORIDA

Louis Perkins became president after Frederick's passing. In 1947, Louis's son, Marvin, joined the company. Expansion continued until they finally ran out of space in Brooklyn.

1947-1960

Roy Hollenbeck came on board in 1960 to plan and coordinate the company's move to North Miami, Florida and oversee construction of the new facility. His extensive experience in manufacturing was instrumental in our successful move from a number of buildings to one large plant with all operations under one roof. Upon the passing of Louis in 1964, Marvin assumed the top responsibility and continued the growth and innovation that exists to this day.

1960-1964

Once settled in Florida, we established our own bronze factory. By 1965, a 47,000 square foot extension was completed, housing the sophisticated die-casting system that today produces zinc, bronze and aluminum products. PERKO® is the only domestic, marine manufacturer producing die-cast bronze parts, well known for strength, uniformity and quality.

1965-1967

Fred Perkins, Marvin's older son, entered the family business in the late 1960's and quickly established himself as one of the marine industry's most knowledgeable authorities on navigational light requirements. In 1977, Perkins Marine Lamp and Hardware Corporation was changed to PERKO®, Inc.

1967-1977

AN INTEGRATED MANUFACTURER

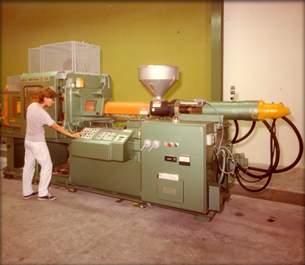

By 1979 we added a 35,000 square foot plastics injection molding facility enabling us to manufacture all of our plastic products and components for our diverse product line.

1979-1980

Today, PERKO® is truly an integrated manufacturer, almost completely independent of outside vendors, with the exception of a few basic items such as light bulbs, electric wire, etc. A whole range of complete in-house capabilities, from product design through manufacturing and assembly of finished products, enable us to eliminate most subcontractors and obtain better control of our product quality and delivery.

1990-1991

Over the years, PERKO® has grown and is now housed in a modern facility, spanning 440,000 square feet on 17 acres in North Miami, Florida. Even now, with 5th generation family control, our business philosophy continues to emphasize long term commitment to quality leadership in the marine industry.

1992-1993

PERKO® IS AN ISO REGISTERED COMPANY

Our employees are an integral part of our business family. They take personal pride in providing individual attention to what they do and how they do it. Their positive attitude insures that each worker properly inspects our products as they are being made, and everyone concentrates on customer satisfaction.

1993-1994

Throughout all of our operations, steps have been taken to efficiently assure production of the highest quality products. PERKO® Inc. has been an ISO registered company since 1994. Our products are designed and manufactured to meet or exceed various standards including ISO 9001:2000, USCG, UL, NMMA and other industry standards, as well as our own quality specifications. Quality control is consistently maintained, and every step forward (from our founding to the present day) has been undertaken with our customer in mind. Each PERKO® product is thoroughly evaluated for safety, appearance and function.

1994-2000

OUR FACTORY

Our sand casting foundries help us control the production of our high quality brass, bronze and aluminum castings, and offers assurance that the proper alloy is used for each job.

2001

Our press department utilizes a variety of forming tools, including multi-stage progressive tooling dies, which we produce in our own tool room. Our large, conventional machine shop includes many secondary operations such as drilling, tapping and assembly. A separate machine shop houses a number of modern, high speed chuckers for high volume items and our three separate polishing divisions assure the correct finishing procedure for each product.

2002

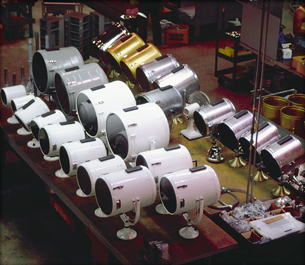

Our plating operation was completely redesigned and rebuilt into a state-of-the-art facility. Special automated controls insure uniformity throughout the complete seven strike chromium plating process. In 2003 a Gold Plating Line was added in order to supply the best electrical contacts in the industry.

2003

"PERKO®, IT'S PROVEN!"

In 2005 our facility was rewired for a state-of-the-art computer network and Enterprise Resource Planning (ERP) operation, which will carry us well into this new century. We are expanding our foundry into Investment Casting. Our in-housing printing, graphics and pre-press department produces almost all of our printed materials from packaging materials, box labels and instructions to full color catalogs and marketing materials. In total, careful planning over the years has enabled us to become virtually self sufficient in every department.

2005

Our current day manufacturing capabilities include:

● An automated foundry, pouring aluminum, bronze and stainless steel

● Decorative chrome plating and electrical contact gold plating

● Computerized CNC machining and robotic grinding

● Zinc alloy, bronze and aluminum die casting

● Plastic injection molding

● Mechanical power press forming operation

● In house tool & die design and production

It has always been our objective to provide our customers with the very best in marine lights, hardware and accessories at competitive prices. Designed and built in America to the highest specifications - "We Make it Right, Right Here!!" All PERKO® products are backed with outstanding warranties and our commitment to excellence.

If it's "PERKO®, it's Proven"! That you can count on!